Trusted Plastic Toy Manufacturer | Prototypes, Molds, Mass Production

Bring Your Plastic Toy Ideas to Life with Reliable Manufacturing Services

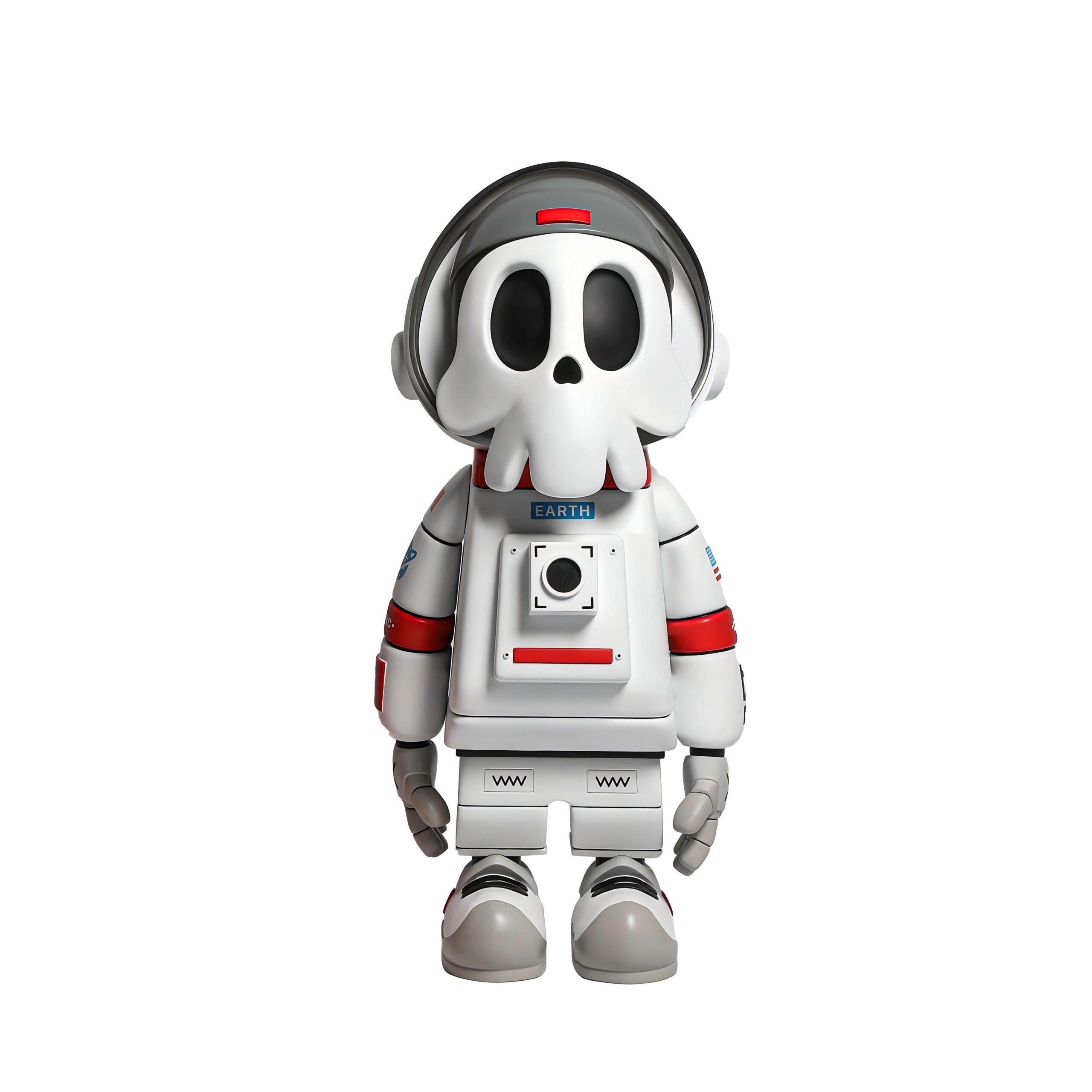

From concept to completion, our expert team offers end-to-end plastic toy manufacturing solutions. With cutting-edge technologies and materials, we specialize in rapid prototyping, precision mold design, and large-scale production, ensuring consistent quality and unmatched efficiency.

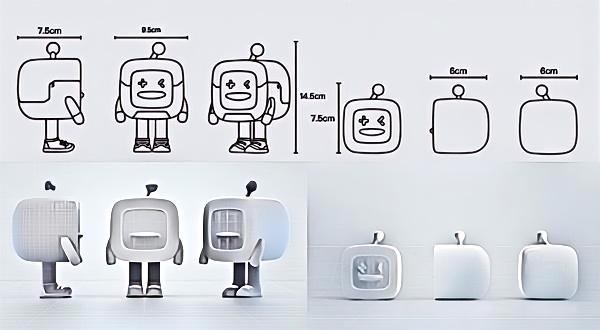

High-Precision Plastic Prototype Making

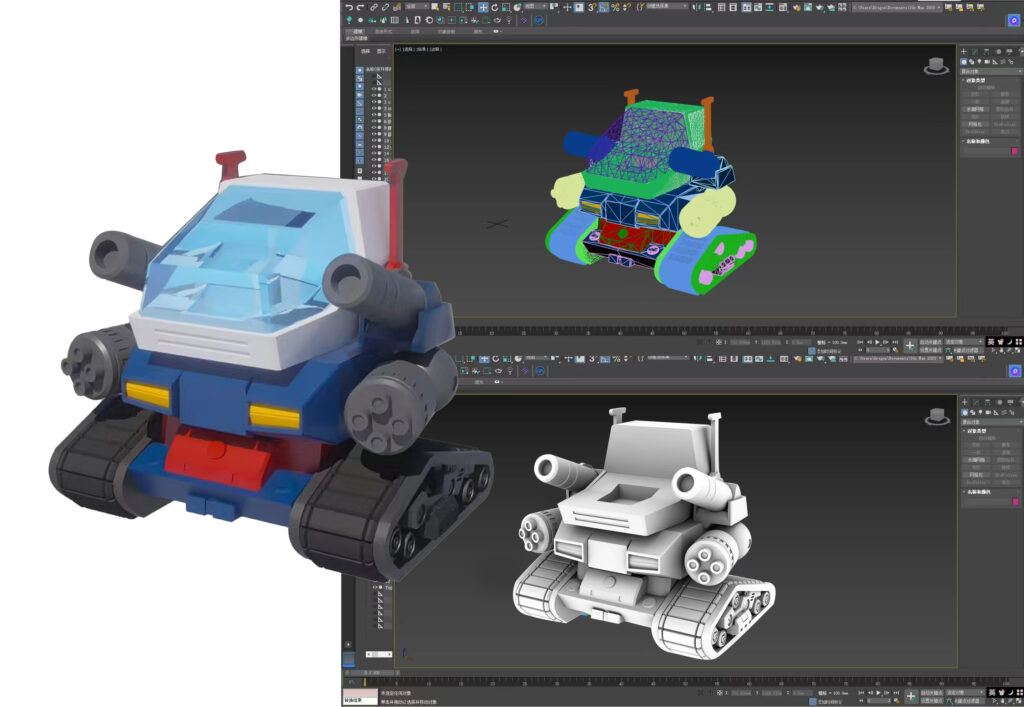

Custom Mold Design & Development for Plastic Toys

Efficient Mass Production of Plastic Products

WORKING WITH KINGDA

“Throughout my career, I’ve encountered select suppliers who feel more like an extension of my own company than external resources. KINGDA tops that list—they consistently go above and beyond to ensure the success of your projects. Their expertise in plastic manufacturing and product development is unbeatable.”

– Sarah Johnson, Senior Product Manager, Global OEM Toys

This testimonial reflects our dedication to delivering precise plastic product design and manufacturing solutions.

Your Challenge- Plastic Product Design and Development Process

Meeting All Your Manufacturing Requirements: Our Production Facilities

Injection Molding

Injection molding is a manufacturing process used to create a wide variety of products by injecting molten material into a mold. This technique allows for high precision and repeatability, making it ideal for producing complex shapes and detailed designs.

Blow Molding

Blow molding is a manufacturing process used to create hollow plastic products by inflating a heated plastic tube, or parison, into a mold. This technique is particularly effective for producing items such as bottles, containers, and other hollow shapes.

Spraying

Spraying is a manufacturing process used to apply a liquid coating or topcoat to a surface, usually for decorative or protective purposes, using specialized equipment to atomize the liquid into a fine mist that is evenly distributed over the target surface.

We can create

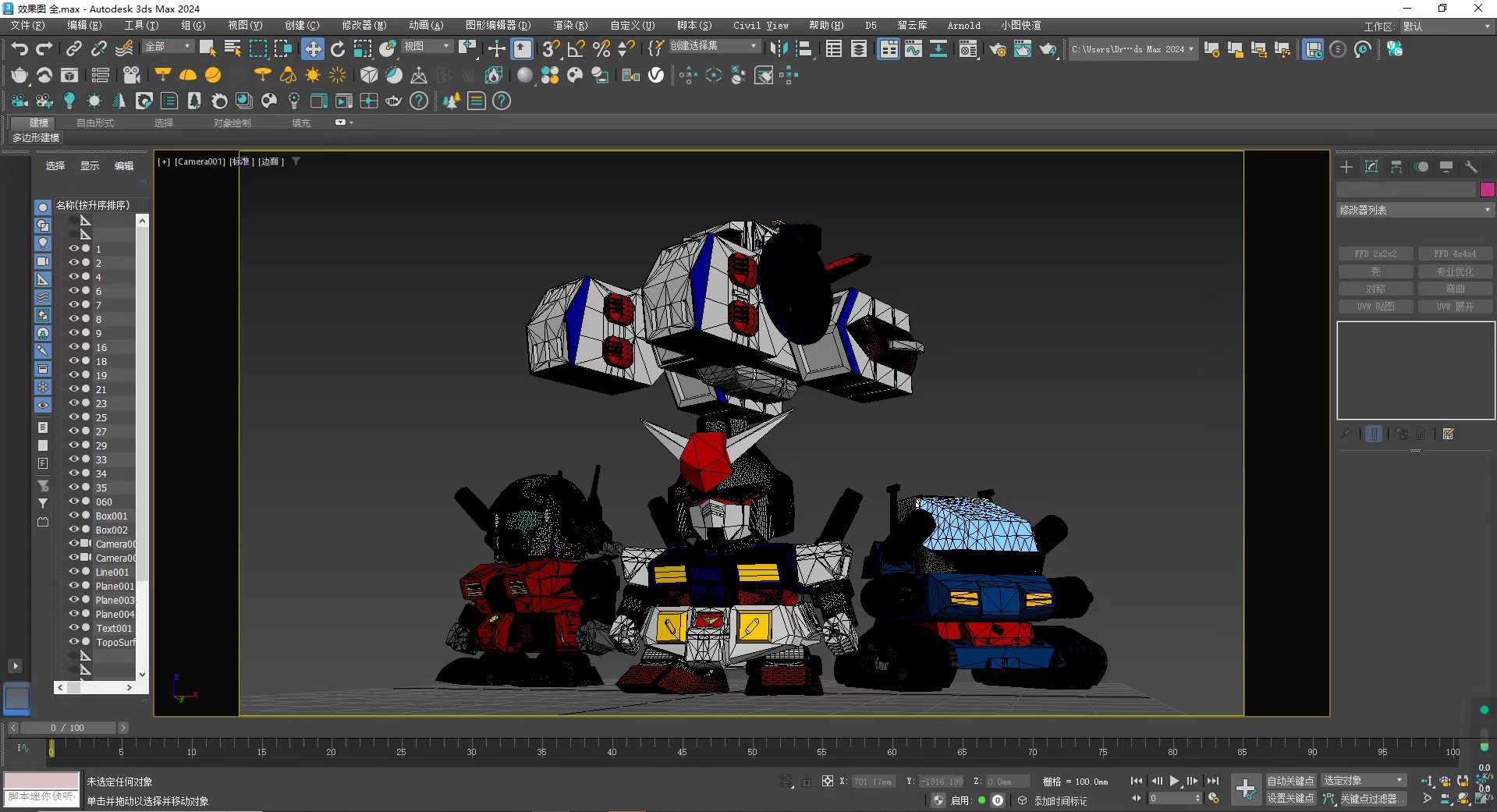

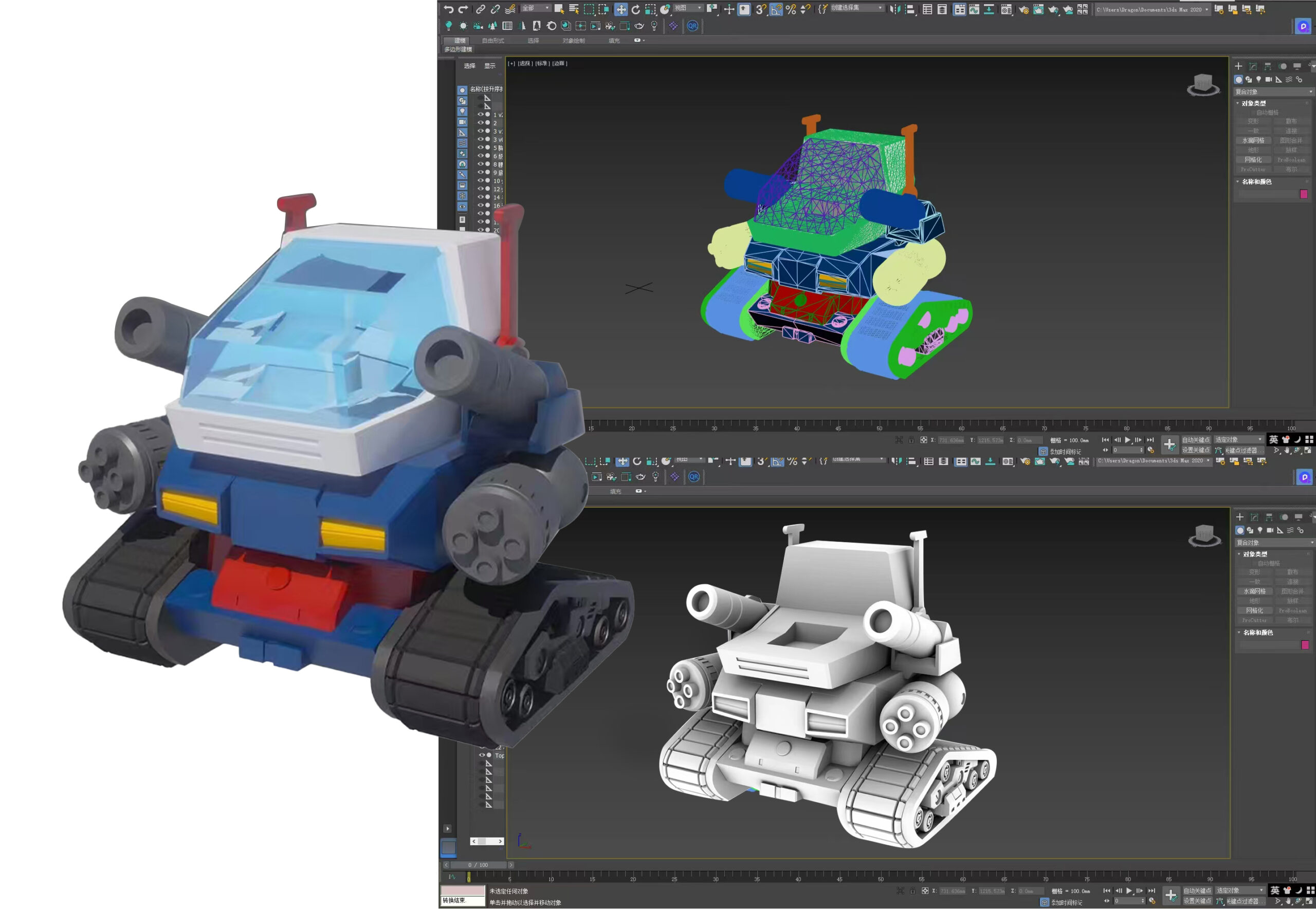

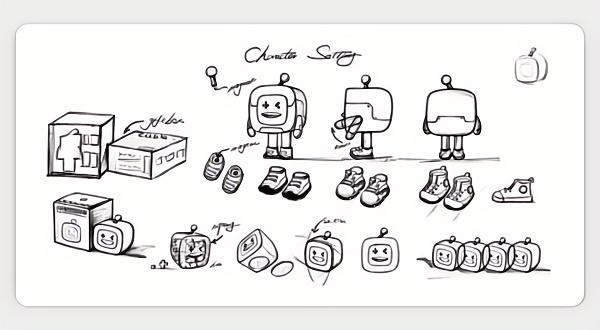

The Toy Creation Process has a series of steps that go from a concept to execution. On the journey of manufacturing a toy, the first thing to do is develop an idea. That tends to be the most challenging part of the process for many entrepreneurs. However, if you have an idea, we can make it happen! Our designers will prepare sketches from the client’s idea, and 3D prototypes, which are great ways to simulate the real product, since their instant graphics can be scaled in size. After all creative processes, we will develop prototypes and move forward to molds before the production.

KingDA International Limited has over 21 years of expertise in global sourcing, manufacturing, and trading solutions. Our dedicated team offers comprehensive, end-to-end services tailored to meet the unique needs of our clients. Whether you’re looking for reliable product sourcing, efficient manufacturing, or seamless global trading services, KingDA delivers customized solutions backed by industry-leading knowledge and experience. We specialize in providing high-quality supply chain management, ensuring the best results for our customers across diverse markets worldwide.

Colors BLACK WITH BLACK, BLACK WITH LIME, BLACK WITH ORANGE, BLACK WITH RED, BLACK WITH WHITE

Delivery Costs – The cost of shipment will vary dependent upon the shipping service, volume, weight, and distance of your order. If you would like to see a more accurate display of the shipping prices, your quotation will include all delivery costs.

Express Service – We have thousands of products that are available with an express service, they are available to ship same day/next day. If your inquiry is urgent, please give us a call on 139 2525 6738

Artwork – Different products have different print processes, dependent on what you are wanting to achieve with your finished product, we will advise on what we believe is the best option for you. If you are wanting more information or advise, please do call us on 1 39 2525 6738.

Vector Files: eps, pdf and ai – Vectored files are suitable for all types of print. Any gradient and tinted areas of your artwork will need to be converted to a solid colour. If you do not hold vectored artwork, please do send us what you have as our design team will be able to help vector your logo/artwork.

Image files: png, jpg and tiff – These formats are only suitable for full colour, process and transfer print. However, if the file is of high resolution then we will be able to have our design team will be able to help vector your logo/artwork.

Invoice/Payment Terms – Payment terms are only offered after necessary checks are carried out and approval is given. A purchase order will be required if terms are approved.

Card – We accept Visa, Mastercard & Amex.

Wire Transfer – Details of payment and account details will be on your invoice after your order is confirmed.

Check – Please make checks payable to Everything Promo.

Disclaimer

The products with customer’s LOGO and printed patterns displayed on this website are only for sample display. The specially designed products, trademarks and copyrighted printed materials displayed on this website belong to the company designated on the printed product.

Six Reasons For People Choosing Us

Quality Material

By utilizing quality materials, manufacturers can enhance the durability, functionality, and aesthetic appeal of their products, ultimately leading to greater customer satisfaction.

Accredited

Accredited by leading organizations such as ICTI, CQC, SCAN, FDA, and ISO, our factory demonstrates a strong commitment to quality and safety standards.

Trained Workers

Specialized training ensures high-quality production, consistency, and adherence to safety standards, contributing significantly to the overall success of our operations.

Time Availability

Factories can quickly adjust production plans based on changes in demand to ensure timely response to market demand.

Quick Response

We will respond quickly and provide answers to your questions to strengthen and maintain long-term customer relationships.

1 Year Warranty

We provide a 1-year warranty to collect user feedback and help the factory improve and enhance the quality of subsequent products.

Step 1: Submit Your Requirements

Share your designs and specifications to start your custom manufacturing journey! Please provide us with your 3D product design drawings, along with details such as plastic material, color, function, and quality standards. We are happy to sign a Non-Disclosure Agreement (NDA) to protect your innovative designs.

Step 2: Confirm the Quotation

Transparent pricing for smooth decisions and flexible production options. We will provide you with a detailed quotation for prototype production (if required), mold manufacturing, unit price for mass production, and an estimated timeline for your review and approval.

Step 3: Design Review

Professional design analysis to optimize production feasibility. Our engineering team will carefully review your design and discuss feasible options and potential production challenges. We’ll offer professional suggestions to enhance profitability and performance, with a focus on cost-effectiveness and functionality.

Step 4: Mold Design Approval

Custom mold designs to kickstart a reliable production process. Once your design is finalized, we will provide a detailed mold design report for your review and approval. This ensures that the design meets exact precision and durability standards.

Step 5: Prototype and Sample Verification

Validate your product with prototype samples to meet your expectations. After completing the mold, we will conduct a trial production and send samples for your review. Together, we will refine the product until it’s 100% ready for mass production.

Step 6: Production Preparation

Streamlined production planning for on-time delivery. Our engineering team will design an effective workflow based on your specifications and quality standards. This workflow will then be passed to our production and quality control teams to ensure your product is manufactured to exact requirements.

Step 7: Quality Inspection

Stringent quality control to ensure every product excels. Once mass production is complete, we will arrange for our QC team to perform comprehensive internal inspections. Alternatively, you can dispatch your own team to our facility for on-site inspections. This guarantees that the final product meets your highest quality expectations.

Step 8: Global Delivery

Safe shipment with reliable delivery to your destination worldwide. After successful quality inspection, we’ll arrange secure transportation for your products. Using trusted logistics partners, we’ll ensure products are safely packaged and efficiently delivered to your specified location anywhere in the world.

Don't Know What To Start With?

Contact us for more information!

Introduction

Our Factory

Kingda, offer full OEM/ODM services, including prototype carving, injection molding, transfer printing, 3D printing, assembly, and packaging.

LonggangStreet, LongganDistrict, ShenzhenCity, GuangdongProvince, China

Phone: +86 13925256738

Email:[email protected]

Free Consultation

Get A Free Quote

- MOQ 1000 sets to customize the product.

MOQ 100 sets to buy our branded product. - Get FREE projects and E-catalog link once you sign up!